Laminated Cardboard Packaging

Laminated Packaging from Cardboard with Custom Print in Bulk from Manufacturer – Packaging production company Cardboard Expert

Description

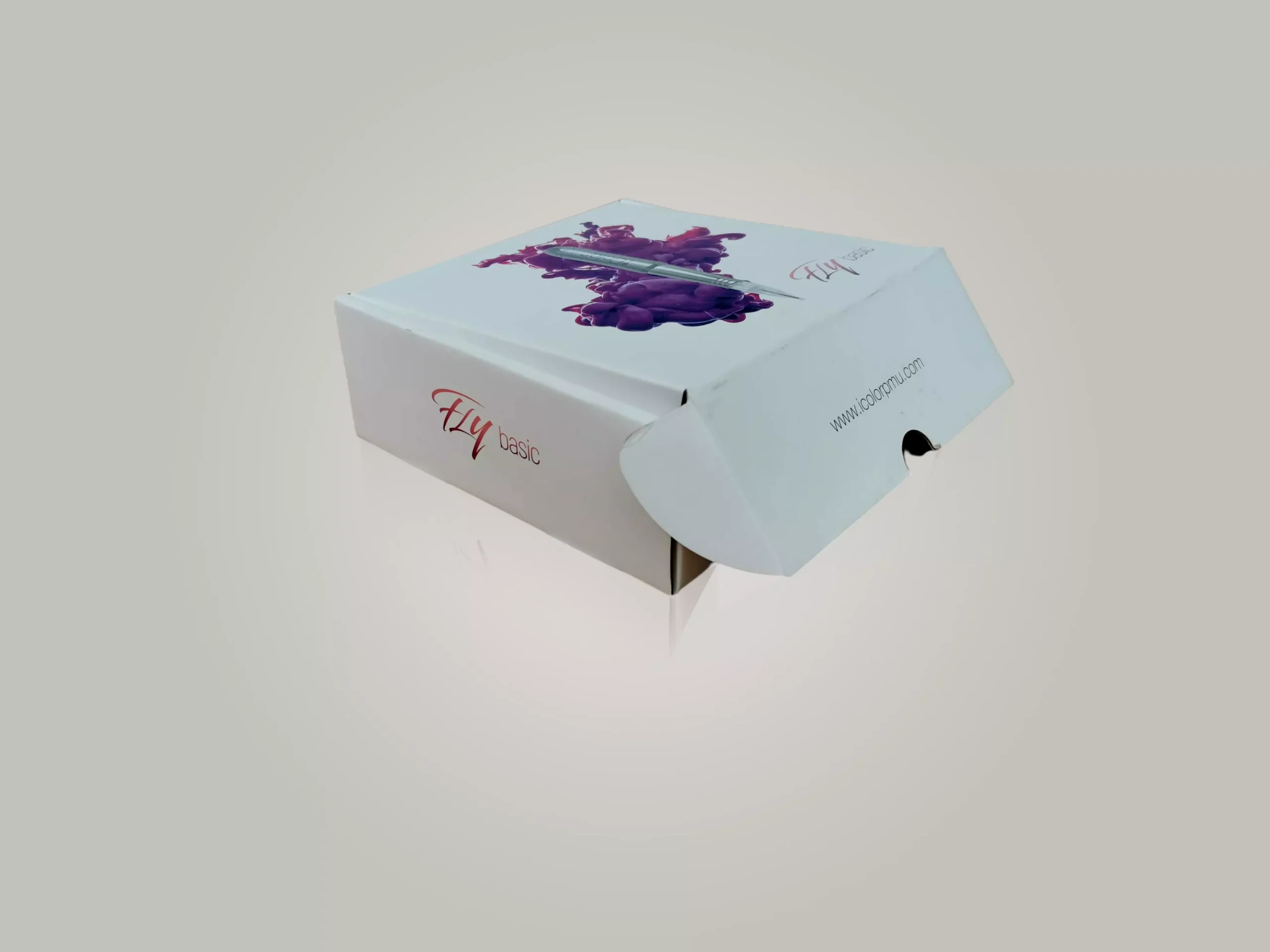

LAMINATED CARDBOARD PACKAGING STANDS FOR A SOLID MARKET POSITION

The paper industry is constantly evolving. It produces more highly efficient products and spends less energy. The applied techniques are now becoming more progressive, often making the process simpler and more efficient at the same time. Laminated or litho packaging is one of these techniques.

THE APPROACH

Laminated boxes packaging is implemented when a printed sheet of paper is laminated (glued) to a piece of sturdy material. Typically, this material is corrugated cardboard. Different printing technologies can be applied for this kind of packaging, for example:

Offset printing. Seems to be a more time-consuming technique, yet, traditionally – a proven method that delivers high-quality results.

Digital printing. Printing on carton boxes can be quick and easy if the electronic file is used as the data storage.

Cardboard Expert offers other printing technologies options. It will depend on your order requirements which we are happy to discuss.

Laminated cardboard boxes could be processed not just from the outside. This technique is also applied to process or ‘glue’ the inside of the packaging.

Laminated carton box processed from both sides. Typically, such boxes are used for transporting or storing the products that should conserve warm temperature. Like, a takeaway coffee.

Litho laminated boxes processed from just outside are meant for storing ‘cold’ products and usually serve a visual purpose.

WHO USES LAMINATED CARDBOARD SHEETS?

Almost every business requires special packaging. However, the widest application is found in the food industry. Now that everyone regularly (or at least once in a while) orders food online – a reliable food box is a must-have.

Disposable tableware. It doesn’t need to be plastic anymore.

Lunch and pizza boxes. Your delicious food will still be warm after delivery took a while.

Coffee cups. Just a comfortable way to drink your coffee on the run.

It is not only about food, though. Laminated corrugated boxes have found their best utilization in other businesses, like electronic device production, decorative boxes, POSM (Point of Sales Materials), etc.

FIVE PROS AND ZERO CONS

Litho laminated cartons have several PROs compared with just raw cardboard.

Laminated boxes for sale are the best solution when reliable packaging has to be attractive. It could have different surface types, like:

Glossy. Such a surface could make the colors richer and brighter. A classic eye-catcher.

Matte. If you want your design to evoke calmer feelings.

Metallic. Silver or gold. You could even create a holographic effect on the box.

An additional layer of the printed paper promises extra resilience to the packaging box, thus allowing to use of a cheaper base material (corrugated cardboard).

The benefit of laminated packaging technology is a low start-up cost which allows small production to run.

Laminated corrugated cardboard is a reliable, resilient, and accessible way of packaging.

It can be re-used and recycled.