Introduction to 5 Ply Corrugated Boxes

In the world of packaging, the durability and reliability of the materials used can make a significant difference in ensuring that products reach their destination safely and securely. One such material that stands out in the packaging industry is the 5 ply corrugated box. Known for its strength and versatility, the 5 ply corrugated box has become a cornerstone in the realm of packaging solutions.

Definition and General Description of 5 Ply Corrugated Boxes

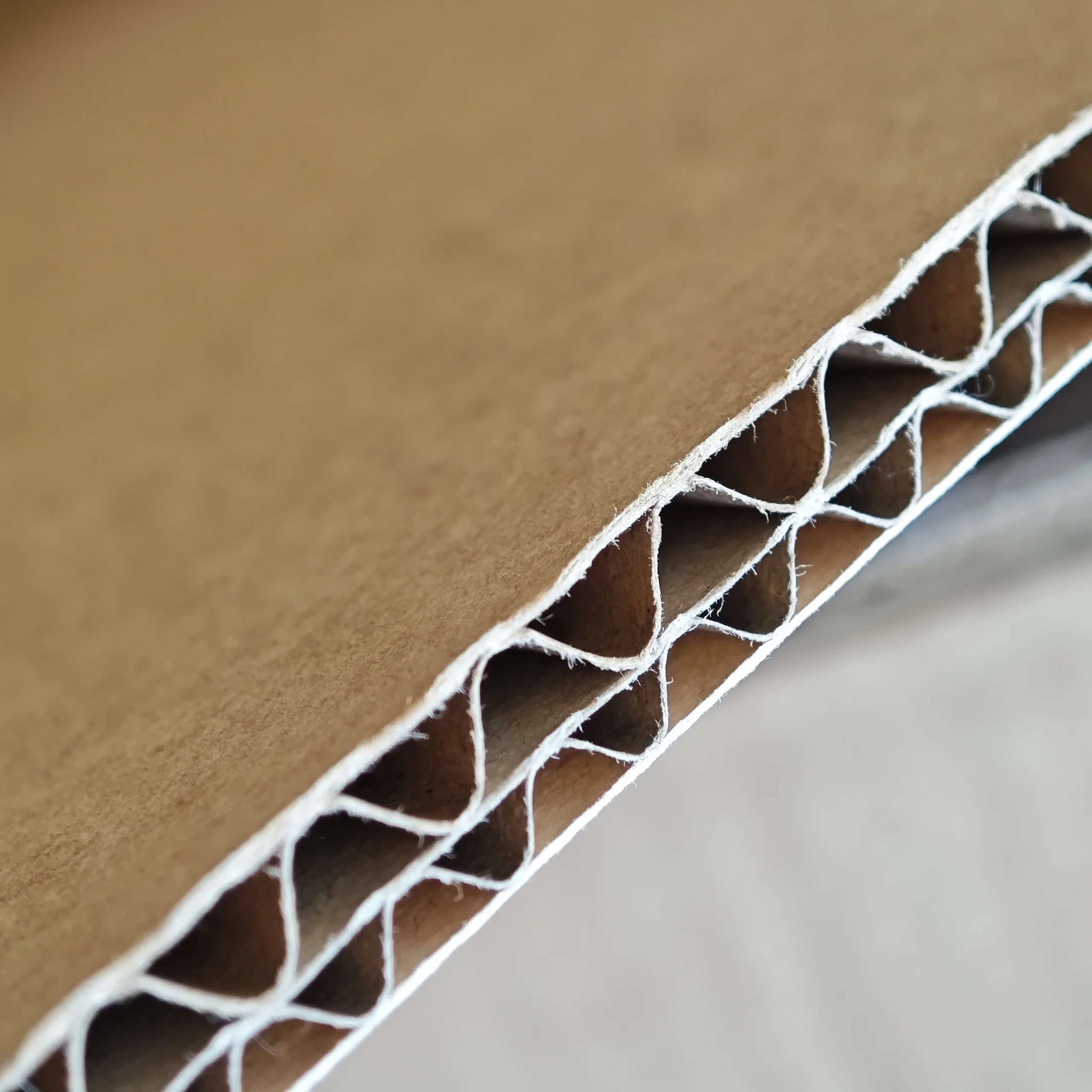

A 5 ply corrugated box is characterized by its multi-layered construction, which consists of five layers: two outer layers of flat linerboard and three inner layers of fluted paper. This configuration not only provides enhanced strength but also offers superior protection for the contents within. The fluted layers act as a cushion, absorbing shocks and preventing damage from impacts during transportation and handling. This makes the 5 ply corrugated box thickness a crucial factor in its overall performance and reliability.

Importance in the Packaging Industry

The importance of 5 ply corrugated boxes in the packaging industry cannot be overstated. These boxes are widely used across various sectors, including electronics, food and beverage, pharmaceuticals, and e-commerce, to name a few. Their robust construction makes them ideal for shipping heavy or fragile items, providing peace of mind to both businesses and consumers. Moreover, the 5 ply corrugated box thickness contributes significantly to the box’s ability to withstand external pressures, ensuring that products remain intact and undamaged.

Overview of the Article’s Structure

This comprehensive guide on 5 ply corrugated box thickness aims to provide readers with an in-depth understanding of this essential packaging material. The article will begin by exploring the detailed construction and benefits of 5 ply corrugated boxes, highlighting why they are preferred in various industries. We will then delve into the environmental impact of using recycled materials in these boxes, emphasizing the sustainability benefits for businesses. Additionally, the article will offer practical tips on selecting the right box thickness for different applications and provide insights into the latest innovations in corrugated packaging technology.

By the end of this guide, readers will have a thorough grasp of the importance of 5 ply corrugated box thickness and how it can enhance their packaging strategies, ensuring both product safety and environmental responsibility.

What is 5 Ply Corrugated Box Thickness?

Explanation of “Ply” and How It Relates to Corrugated Boxes

In the packaging industry, the term “ply” refers to the number of layers of paperboard used in the construction of corrugated boxes. Each layer contributes to the overall strength, durability, and cushioning properties of the box. Corrugated boxes are typically made of two types of layers: flat linerboard and corrugated (fluted) paper. The combination of these layers creates a strong, lightweight, and protective packaging solution.

A 5 ply corrugated box consists of five layers: two outer flat linerboards and three inner layers of corrugated fluted paper. This configuration enhances the box’s ability to withstand impacts, compression, and other stresses during shipping and handling.

Specific Details About the Thickness of 5 Ply Corrugated Boxes

The thickness of a 5 ply corrugated box is a crucial factor in its performance. The fluted layers, positioned between the flat linerboards, create air pockets that act as a cushion, absorbing shocks and protecting the contents. The exact thickness of a 5 ply corrugated box can vary depending on the type of fluting used (e.g., A-flute, B-flute, C-flute, etc.), but it generally ranges between 6mm to 7mm.

The strength of a 5 ply corrugated box is derived from its multi-layered construction. Each layer adds to the box’s overall rigidity and ability to protect the contents from external forces. This makes 5 ply corrugated boxes ideal for packaging heavy, fragile, or valuable items that require extra protection during transit.

Comparison with Other Ply Levels (e.g., 3 Ply, 7 Ply)

Understanding how 5 ply corrugated boxes compare to other ply levels is essential for choosing the right packaging solution. Here’s a brief comparison:

- 3 Ply Corrugated Boxes: These boxes have a simpler construction with two outer linerboards and one inner fluted layer. They are thinner and less robust than 5 ply boxes, typically measuring around 3mm in thickness. 3 ply boxes are suitable for lighter items and shorter shipping distances.

- 5 Ply Corrugated Boxes: As described, these boxes offer a middle ground in terms of strength and thickness. They are versatile and widely used for a variety of shipping needs, providing a good balance between weight and protection.

- 7 Ply Corrugated Boxes: These boxes feature seven layers: three outer linerboards and four inner fluted layers. They are the thickest and strongest among common corrugated boxes, with a thickness ranging from 9mm to 10mm. 7 ply boxes are used for extremely heavy or delicate items that need maximum protection during long-distance or international shipping.

In summary, the 5 ply corrugated box thickness provides a robust and reliable packaging solution suitable for a wide range of applications. Its multi-layered structure ensures optimal protection for products, making it a preferred choice in various industries. Understanding the differences in ply levels helps businesses select the most appropriate packaging for their specific needs, balancing protection, cost, and environmental considerations.

The Manufacturing Process of 5 Ply Corrugated Boxes

Materials Used in Manufacturing

The manufacturing of 5 ply corrugated boxes begins with the selection of high-quality materials. The primary materials used include:

- Kraft Paper: This durable, high-strength paper is used for both the outer linerboards and the inner fluted layers. It is typically made from wood pulp or recycled paper.

- Adhesive: A strong, water-based adhesive is used to bond the layers together, ensuring the integrity of the box.

These materials are chosen for their strength, durability, and eco-friendliness, contributing to the overall quality and sustainability of the final product.

Step-by-Step Process of Creating 5 Ply Corrugated Boxes

- Preparation of Materials:

- The manufacturing process starts with large rolls of kraft paper being loaded into the corrugating machine. The paper is unwound and fed into the machine, where it is preconditioned with steam to enhance its pliability and bonding properties.

- Corrugating:

- The next step involves forming the fluted layers. The kraft paper passes through a series of corrugating rollers that shape it into a wavy, fluted structure. The number of corrugating rollers and the type of flute (e.g., A-flute, B-flute) determine the final thickness and strength of the fluted layer.

- Lamination:

- The fluted paper is then bonded to the flat linerboards using a water-based adhesive. In the case of 5 ply corrugated boxes, this process involves three stages of lamination:

- The first linerboard is glued to one side of the first fluted layer.

- Another fluted layer is glued to the opposite side of the first linerboard, creating a three-layered structure.

- This process is repeated with additional fluted layers and linerboards to achieve the final five-layer structure.

- The fluted paper is then bonded to the flat linerboards using a water-based adhesive. In the case of 5 ply corrugated boxes, this process involves three stages of lamination:

- Cutting and Scoring:

- The laminated corrugated board is then cut and scored into the desired dimensions using a die-cutting machine. Scoring creates fold lines, making it easier to assemble the box without damaging the material.

- Assembly:

- The cut and scored sheets are then folded and glued into their final box shape. This step can be done manually or with the help of automated machines, depending on the production scale and box design.

Quality Control Measures

To ensure the highest quality standards, several quality control measures are implemented throughout the manufacturing process:

- Material Inspection:

- Raw materials, including kraft paper and adhesive, are inspected for quality and consistency before entering the production line. This ensures that only top-grade materials are used in the manufacturing process.

- Process Monitoring:

- During production, various parameters such as temperature, pressure, and adhesive application are continuously monitored and adjusted to maintain optimal conditions. This helps in producing uniform and reliable corrugated boards.

- Strength Testing:

- Samples from each batch are subjected to rigorous strength tests, including edge crush tests (ECT) and burst tests, to verify their load-bearing capacity and resistance to external pressures.

- Visual Inspection:

- Finished boxes are visually inspected for defects such as misalignment, improper bonding, or surface irregularities. Any defective boxes are removed from the production line to ensure only high-quality products reach the customers.

By adhering to these stringent quality control measures, manufacturers can guarantee that 5 ply corrugated boxes meet the necessary standards for strength, durability, and reliability, making them a trusted choice for a wide range of packaging needs.

Applications of 5 Ply Corrugated Boxes in Various Industries

The versatility and strength of 5 ply corrugated boxes make them indispensable across a variety of industries. Their robust construction ensures that goods are transported safely and efficiently, meeting the high standards required in diverse sectors.

Use in Retail and E-Commerce

In the retail and e-commerce sectors, 5 ply corrugated boxes are essential for packaging and shipping a wide range of products. The rise of online shopping has amplified the need for reliable packaging solutions that can withstand the rigors of transportation while protecting the integrity of the contents.

- Protection During Transit: The multi-layered structure of 5 ply corrugated boxes provides excellent protection against impacts, vibrations, and compression. This is particularly important for e-commerce businesses, where packages often travel long distances and go through multiple handling points before reaching the customer.

- Versatility: These boxes are suitable for various products, from clothing and accessories to household items and books. Their ability to be customized in terms of size and shape makes them ideal for different packaging requirements.

- Branding Opportunities: Retail and e-commerce businesses can also use 5 ply corrugated boxes as a branding tool. The smooth outer surface of the boxes can be printed with logos, brand messages, and other promotional graphics, enhancing the unboxing experience for customers and reinforcing brand identity.

Application in Food and Beverage Industry

The food and beverage industry relies heavily on 5 ply corrugated boxes for the safe transport and storage of products. These boxes meet the strict standards for hygiene and safety required in this sector.

- Food Safety: 5 ply corrugated boxes are often made from food-grade materials that do not contaminate the contents. This is crucial for transporting perishable items such as fruits, vegetables, and baked goods.

- Temperature Regulation: The thick, multi-layered construction provides some insulation, helping to maintain the temperature of refrigerated and frozen goods during transit. This is essential for products that need to remain at a constant temperature to ensure freshness and prevent spoilage.

- Durability: The boxes can withstand moisture and rough handling, protecting beverages like bottled water, juices, and alcoholic drinks from damage. Their stackability also makes them ideal for efficient storage in warehouses and retail outlets.

Utilization in Electronics and Fragile Goods Shipping

Shipping electronics and other fragile items requires packaging that offers superior protection against shocks, drops, and other potential damages. 5 ply corrugated boxes are perfectly suited for this purpose.

- Shock Absorption: The fluted layers within the box act as a cushion, absorbing shocks and vibrations that occur during transportation. This minimizes the risk of damage to delicate electronic components such as smartphones, laptops, and other gadgets.

- Anti-Static Properties: Some 5 ply corrugated boxes are treated with anti-static materials, which are essential for shipping sensitive electronic equipment that can be damaged by static electricity.

- Custom Inserts: To provide additional protection, these boxes can be designed with custom inserts that hold electronic devices securely in place. Foam inserts, dividers, and other cushioning materials can be added to ensure that each item is immobilized and protected from all sides.

In conclusion, the applications of 5 ply corrugated boxes in various industries underscore their importance as a reliable and versatile packaging solution. From retail and e-commerce to the food and beverage industry, and the shipping of electronics and fragile goods, these boxes offer unmatched strength and protection. Their adaptability to different packaging needs makes them an essential component in the supply chain, ensuring that products reach their destination safely and in optimal condition.

Business Considerations When Choosing 5 Ply Corrugated Boxes

Selecting the right packaging solution is crucial for businesses aiming to balance cost efficiency, product protection, and customer satisfaction. 5 ply corrugated boxes offer several business advantages, making them a popular choice across various industries. Here are key business considerations when choosing 5 ply corrugated boxes:

Cost Analysis

Cost is a fundamental factor for any business decision, and 5 ply corrugated boxes present a cost-effective solution for several reasons:

- Durability and Protection: While 5 ply corrugated boxes may have a higher upfront cost compared to lower ply options, their durability ensures better protection for products during transit. This reduces the likelihood of product damage and associated costs of returns, replacements, and customer dissatisfaction.

- Bulk Purchasing: Many suppliers offer discounts for bulk purchases of 5 ply corrugated boxes, which can significantly reduce the per-unit cost. Businesses with high packaging needs can benefit from these economies of scale.

- Reusability: If well constructed (best choice), they could be used numerous times hence suitable as a CAD and CAM for internal logistics, but also for returning products. It is also attractive due to the reusability it could provide over time, cost savings.

Customization Options

Customization is an important consideration for businesses looking to enhance their brand presence and meet specific packaging requirements:

- Size and Shape: 5 ply corrugated boxes can be customized to fit products of various dimensions, ensuring a snug fit that minimizes movement and potential damage during shipping.

- Printing and Branding: These boxes offer excellent surfaces for high-quality printing. Businesses can customize their boxes with logos, brand colors, and other promotional graphics. This not only enhances brand recognition but also improves the unboxing experience for customers, which can be a significant differentiator in competitive markets.

- Special Features: Customization can also include adding special features like die-cut handles, perforations, or reinforced corners. These enhancements can improve functionality and user convenience, adding value to the packaging.

Logistics and Storage Advantages

Efficient logistics and storage are critical for maintaining a smooth supply chain and optimizing operational costs:

- Space Efficiency: 5 ply corrugated boxes are designed to be stackable, maximizing storage space in warehouses and during transport. Their strength ensures that they can bear the weight of stacking without collapsing, which is essential for efficient space utilization.

- Weight Considerations: Despite their strength, 5 ply corrugated boxes are relatively lightweight. This helps in reducing shipping costs, especially when shipping rates are calculated based on weight.

- Flat Packing: These boxes can be shipped and stored flat before assembly, saving valuable storage space. Businesses can assemble them as needed, ensuring that storage facilities are used efficiently and that there is no unnecessary occupation of space.

- Sustainability: Many logistics companies and customers are increasingly prioritizing sustainability. Using 5 ply corrugated boxes made from recycled materials can enhance a company’s reputation as an environmentally responsible business, potentially attracting eco-conscious customers and partners.

In conclusion, choosing 5 ply corrugated boxes offers businesses a balanced solution of durability, customization, and logistical efficiency. By conducting a thorough cost analysis, exploring customization options, and leveraging the logistical advantages, businesses can optimize their packaging strategies to support both operational efficiency and brand growth.

How to Measure 5 Ply Corrugated Box Thickness

Measuring the thickness of a 5 ply corrugated box is crucial to ensure it meets the required standards for durability and protection. Accurate measurement helps in quality control and in selecting the right packaging for specific needs. Here’s a guide on how to measure the thickness of 5 ply corrugated boxes:

Tools Required for Measuring Thickness

To measure the thickness of a 5 ply corrugated box, you will need the following tools:

- Digital Caliper or Micrometer: These tools provide precise measurements of the box thickness. Digital calipers are easy to read and can measure with high accuracy.

- Ruler or Tape Measure: While less precise, a ruler or tape measure can be used for a general estimation of the box thickness.

- Flat Surface: A stable, flat surface is essential for placing the box while measuring to ensure accuracy.

Step-by-Step Measuring Guide

- Prepare the Box:

- The 5 ply corrugated box should be placed on a flat surface in order to avoid being unsteady or warped/bended. So use it to get accurate measure

- Using a Digital Caliper or Micrometer:

- Open the jaws of the caliper or micrometer and place them around the edge of the box where you want to measure the thickness.

- Gently close the jaws until they touch the surfaces of the box without compressing it.

- The reading will then be viewable upon the digital screen. Read the measurement from the scale in a micrometer

- Record the measurement. Repeat the process at several points along the edge of the box to ensure consistency and accuracy.

- Using a Ruler or Tape Measure:

- If a digital caliper or micrometer is not available, use a ruler or tape measure to estimate the thickness.

- Place the ruler or tape measure along the edge of the box.

- Ensure the measuring tool is perpendicular to the edge to avoid skewed readings.

- Read and record the measurement. While this method is less precise, it can give a reasonable estimate of the box thickness.

Ensuring Accuracy in Measurement

To ensure accuracy in measuring the thickness of a 5 ply corrugated box, follow these best practices:

- Multiple Measurements: Take measurements at several points along the edges of the box and average them to get an accurate thickness. This accounts for any variations in the material.

- Consistent Pressure: When using a caliper or micrometer, apply consistent pressure to avoid compressing the corrugated layers, which can lead to incorrect readings.

- Calibration: Ensure that your measuring tools are properly calibrated before use. Regularly check and calibrate digital calipers and micrometers to maintain their accuracy.

- Clean Tools and Surfaces: Make sure the measuring tools and the box surface are clean and free of debris, as dirt can affect the accuracy of the measurements.

By following this guide, you can accurately measure the thickness of 5 ply corrugated boxes, ensuring they meet the necessary standards for strength and durability. Accurate measurements are essential for quality control and for selecting the appropriate packaging to protect your products during transit.

Conclusion

In this comprehensive guide, we have explored the essential aspects of 5 ply corrugated box thickness, highlighting its significance in the packaging industry. From understanding the detailed construction and benefits of these boxes to examining their applications across various industries, the importance of selecting the right box thickness has been underscored.

Recap of the Main Points

5 ply corrugated boxes are constructed with five layers, including two outer linerboards and three inner fluted layers, providing superior strength and durability. These boxes are essential for protecting products during transit, making them ideal for use in retail, e-commerce, food and beverage, and electronics industries. We have also discussed the environmental benefits of using recycled materials in manufacturing these boxes, which helps reduce carbon footprints and promotes sustainability. Additionally, the manufacturing process, business considerations, and accurate measurement techniques were covered to provide a holistic understanding of these packaging solutions.

Final Thoughts on the Importance of 5 Ply Corrugated Box Thickness

The thickness of 5 ply corrugated boxes plays a critical role in their performance. Ensuring the right thickness not only protects the products inside but also enhances the efficiency of the supply chain, reduces costs, and supports sustainability goals. As businesses continue to prioritize eco-friendly practices, the use of durable and recyclable packaging like 5 ply corrugated boxes becomes increasingly important. They offer a balanced solution that meets both environmental and economic needs, making them a preferred choice for many industries.

Finally

For businesses looking to enhance their packaging strategies, understanding the benefits and proper use of 5 ply corrugated boxes is crucial. Pack Expert OU specializes in providing high-quality cardboard packaging solutions tailored to meet your specific needs. Contact Pack Expert OU today to learn more about how 5 ply corrugated boxes can benefit your business. Our team of experts is ready to assist you in selecting the perfect packaging solutions that ensure the safety of your products while promoting sustainability.

By choosing 5 ply corrugated boxes from Pack Expert OU, you are not only investing in the protection of your products but also contributing to a greener future. Let us help you make the best packaging decisions for your business needs.