Introduction to Custom Cardboard Packaging

In today’s competitive market, the significance of packaging extends far beyond mere protection of the product. It plays a crucial role in marketing, brand recognition, and consumer engagement. Custom cardboard packaging has emerged as a powerful tool for businesses looking to differentiate themselves and create a lasting impression on their customers. One of the most effective ways to achieve this is through cardboard packaging with your own print.

Custom cardboard packaging allows businesses to infuse their brand identity into every aspect of their packaging. From the moment a customer receives a package, they are greeted with a unique design that reflects the brand’s values, personality, and promise. This initial interaction can significantly influence their perception of the product and the company. With the right design, custom cardboard packaging can turn a simple unboxing experience into a memorable event that encourages repeat purchases and brand loyalty.

The benefits of using cardboard packaging with your own print are manifold. Firstly, it provides an excellent opportunity for branding. Every box, carton, or sleeve becomes a canvas for the brand’s logo, colors, and messaging. This consistent exposure reinforces brand recognition and helps establish a strong presence in the market. Secondly, custom printing allows for greater flexibility and creativity in design. Businesses can experiment with different styles, themes, and promotional messages, adapting to seasonal trends or specific marketing campaigns.

Furthermore, custom cardboard packaging is an eco-friendly option. Cardboard is 100% biodegradable, recyclable and largely made from renewable resources. Using cardboard packaging and eco-friendly inks as well sustainable practices, advances a business’s appeal with such of the green market helping efforts for Corporate Social Responsibility. That shift supports increasing consumer appetite for sustainable and ethically sourced products.

In addition to these benefits, cardboard packaging with your own print can also contribute to cost savings. By optimizing the design and size of the packaging, businesses can reduce material waste and shipping costs. Customized packaging can be tailored to fit the product perfectly, minimizing the need for additional packing materials and ensuring efficient use of space during transportation.

In conclusion, cardboard packaging with your own print is not just a packaging solution; it’s a strategic marketing tool that can elevate your brand, enhance customer experience, and promote sustainability. As we delve deeper into the design and production process in the subsequent sections, you’ll discover how to make the most of this versatile and impactful packaging option.

Understanding Your Brand’s Aesthetic

Creating effective cardboard packaging with your own print begins with a deep understanding of your brand’s aesthetic. Your packaging should serve as a direct reflection of your brand’s identity, communicating your values and personality to consumers at a glance. Here’s how to align your packaging design with your brand’s aesthetic:

Importance of Brand Identity in Packaging

Brand identity encompasses the visual elements that distinguish your brand from competitors. It includes your logo, color scheme, typography, and overall design style. When designing cardboard packaging with your own print, these elements should be consistently incorporated to create a cohesive brand image. Consistency in design helps to build brand recognition, making it easier for customers to identify your products in a crowded marketplace.

For instance, if your brand is known for its eco-friendly products, your packaging should reflect this through the use of natural colors, recycled materials, and minimalistic design. On the other hand, if your brand is luxurious and high-end, sleek and elegant designs with sophisticated color palettes and high-quality printing techniques will be more appropriate.

How to Align Packaging Design with Brand Aesthetics

To ensure that your cardboard packaging aligns with your brand’s aesthetics, start by defining your brand’s core attributes. Ask yourself the following questions:

- What are the key values and messages my brand aims to convey?

- Who is my target audience and what are their preferences?

- What emotions do I want my packaging to evoke?

Once you have a clear understanding of your brand’s identity, translate these attributes into your packaging design. Here are some tips:

- Logo Placement: Your logo is a central element of your brand identity. Make sure it is visibly displayed on your packaging. It should be easily visible and positioned in a way that catches the customer’s eye immediately.

- Color Scheme: Use your brand’s color palette consistently across all packaging materials. Colors play a significant role in brand recognition and can influence consumer behavior. Select colors that reflect your brand’s spirit and appeal to your target audience.

- Typography: Select fonts that are consistent with your brand’s style. The typography should be legible and convey the right tone, whether it’s playful, professional, modern, or classic.

- Imagery and Graphics: Incorporate imagery and graphics that resonate with your brand’s identity. Whether it’s minimalist icons, detailed illustrations, or high-quality photographs, ensure they complement the overall design and messaging.

Examples of Brands with Strong Packaging Identities

Examining successful brands with strong packaging identities can provide inspiration and insights into effective design strategies. For example:

- Apple: Apple’s packaging is synonymous with simplicity and elegance. Their use of clean lines, minimal text, and high-quality materials reflects their brand’s commitment to innovation and premium quality.

- Lush Cosmetics: Lush uses recycled materials and bold, handwritten fonts to emphasize their eco-friendly and handmade products. Their packaging design aligns perfectly with their brand values of sustainability and ethical sourcing.

- Tiffany & Co.: The iconic Tiffany Blue Box is instantly recognizable and exudes luxury. The consistent use of their signature blue color, along with elegant ribbon accents, reinforces their brand’s image of timeless elegance and sophistication.

In summary, understanding and aligning your packaging design with your brand’s aesthetic is crucial for creating effective cardboard packaging with your own print. By ensuring consistency in visual elements and staying true to your brand’s identity, you can create packaging that not only protects your product but also enhances your brand’s presence and appeal in the market.

Choosing the Right Colors and Fonts for Cardboard Packaging

Designing impactful cardboard packaging with your own print requires careful consideration of colors and fonts. These elements play a critical role in conveying your brand message and influencing consumer perception. Here’s how to choose the right colors and fonts for your custom packaging:

The Psychology of Colors in Packaging Design

Colors are powerful tools in packaging design, as they can evoke emotions and associations that influence consumer behavior. Understanding the psychology of colors can help you choose the right palette for your cardboard packaging with your own print:

- Red: Often associated with excitement, passion, and urgency. It can stimulate appetite, making it a popular choice for food packaging.

- Blue: Conveys trust, reliability, and calmness. It is commonly used in packaging for tech products, healthcare, and finance.

- Green: Symbolizes nature, health, and sustainability. It is ideal for eco-friendly products and brands emphasizing natural ingredients.

- Yellow: Represents happiness, optimism, and warmth. It can grab attention and is often used for children’s products and affordable goods.

- Black: Exudes luxury, sophistication, and elegance. It is frequently used in high-end product packaging to create a premium feel.

- White: Suggests purity, simplicity, and cleanliness. It is versatile and can be paired with any other color to create a modern, minimalist look.

Choosing the right color scheme for your cardboard packaging with your own print should align with your brand’s identity and the emotions you want to evoke in your customers.

Choosing Fonts that Represent Your Brand

Fonts are equally important in packaging design, as they contribute to the readability and overall aesthetic of your packaging. Here is how you can find out the right font:

- Legibility: Ensure that your chosen fonts are easy to read, even from a distance. Avoid overly intricate or decorative fonts that may be hard to decipher.

- Consistency: Use a consistent font family across all packaging materials to maintain a cohesive brand identity. Mixing too many fonts can create a cluttered and unprofessional look.

- Tone: Choose fonts that match the tone of your brand. For example, a playful and fun brand might use a bold, rounded font, while a luxury brand might opt for a sleek, serif typeface.

- Hierarchy: Establish a clear hierarchy with your fonts to guide the customer’s eye to the most important information first. Use different weights and sizes to differentiate between headings, subheadings, and body text.

Tips on Color and Font Combinations That Work Well

Combining the right colors and fonts can create a visually appealing and effective packaging design. Here is how you can find out exactly you need:

- Contrast: Choose constrast colors for text to make it easy readable. For example, dark text on a light background or vice versa creates a clear contrast that is easy to read.

- Harmony: Choose colors and fonts that complement each other and create a harmonious look. Avoid clashing colors or mismatched fonts that can make your packaging look disjointed.

- Brand Alignment: Ensure that your color and font choices align with your brand’s overall aesthetic. For instance, if your brand has a vintage feel, consider using retro-inspired colors and fonts.

- Testing: Create mock-ups of your packaging design and test them with a focus group or a sample audience. Gather feedback on the color and font choices to make any necessary adjustments before final production.

In conclusion, choosing the right colors and fonts is essential for creating effective cardboard packaging with your own print. By understanding the psychology of colors, selecting legible and consistent fonts, and ensuring harmonious combinations, you can design packaging that not only captures attention but also reinforces your brand’s identity and values.

The Printing Process: How to Get Your Design on Cardboard

Designing compelling cardboard packaging with your own print is just the beginning. Understanding the printing process is crucial to bringing your designs to life with the quality and precision your brand deserves. Here’s a detailed guide to the different printing methods and the steps involved in getting your design onto cardboard packaging.

Overview of Different Printing Methods

- Digital Printing

- Pros: Ideal for short runs and quick turnarounds, offers high-quality prints, and is cost-effective for small batches.

- Cons: Generally more expensive per unit for large runs compared to other methods.

- Best For: Personalized packaging, prototypes, and small-to-medium production runs.

- Offset Printing

- Pros: High-quality images, cost-effective for large runs, and capable of producing consistent colors.

- Cons: Higher initial setup cost, not economical for short runs. Suitable only for thin cardboard up to 0.6mm thickness.

- Best For: Large volume orders and designs requiring detailed, high-resolution images on thin cardboard.

- Flexographic Printing

- Pros: Suitable for printing on various substrates, high-speed production, and cost-effective for large runs.

- Cons: Lower quality compared to digital and offset printing, higher initial setup costs. Suitable only for corrugated cardboard.

- Best For: Large-scale production of packaging that does not require high-resolution images, specifically for corrugated cardboard.

- Screen Printing

- Pros: Versatile and can be used on various materials, offers vibrant colors, and is cost-effective for medium runs.

- Cons: Not suitable for high-resolution images, labor-intensive setup.

- Best For: Medium runs, especially for designs with bold colors and simple graphics.

Pros and Cons of Each Printing Method

Understanding the advantages and disadvantages of each printing method can help you choose the best option for your cardboard packaging with your own print:

- Digital Printing: Offers flexibility and high quality but is more expensive for large quantities.

- Offset Printing: Provides high-quality prints at a lower cost for large runs but has a higher initial setup cost and is limited to thin cardboard.

- Flexographic Printing: Suitable for high-speed production and various substrates but may not deliver the same quality as digital or offset printing and is limited to corrugated cardboard.

- Screen Printing: Ideal for bold, vibrant designs on various materials but not suitable for detailed images or high-resolution graphics.

Additional Finishing Techniques

- Hot Foil Stamping

- Pros: Adds a luxurious, eye-catching metallic finish to the packaging. It is durable and provides a high-end look.

- Cons: Higher cost compared to standard printing methods.

- Best For: Premium products and brands looking to add a touch of elegance to their packaging.

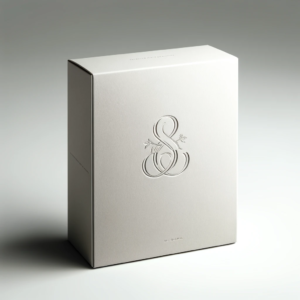

- Embossing

- Pros: Creates a raised texture on the packaging, adding a tactile dimension and enhancing the visual appeal.

- Cons: Additional cost and complexity in the production process.

- Best For: Highlighting logos, text, or specific design elements to create a more distinctive and premium feel.

- UV Varnishing

- Pros: Adds a glossy, high-shine finish to the packaging, enhancing its durability and aesthetic appeal. It can be applied selectively to highlight specific areas.

- Cons: Additional cost and requires special handling during production.

- Best For: Protecting the print and adding a professional, polished look to the packaging.

Step-by-Step Guide to the Printing Process

- Design Finalization

- Ensure your design is finalized and ready for print. This includes confirming all colors, fonts, and images are correctly formatted and aligned with your brand’s guidelines.

- Choosing the Printing Method

- Based on your production volume, budget, and quality requirements, select the most appropriate printing method.

- Creating Print-Ready Files

- Convert your design into print-ready files. Typically, this involves using vector formats (such as AI, EPS, or PDF) to ensure the design can be scaled without loss of quality. Ensure the color mode is set to CMYK, as this is standard for printing.

- Proofing

- Request a proof from your printer to check for any errors or adjustments needed. This step is crucial to ensure that the final output matches your expectations.

- Printing Plates (if applicable)

- For methods like offset or flexographic printing, create printing plates. These plates transfer the design onto the cardboard during the printing process.

- Printing

- Begin the printing process. Monitor the initial print run to check for quality and consistency. Make any necessary adjustments early to avoid wasting materials.

- Finishing Touches

- Apply any finishing touches such as hot foil stamping, embossing, or UV varnishing. These can enhance the visual appeal and durability of your packaging.

- Quality Control

- Conduct a thorough quality control check to ensure that all packaging meets your standards. Look for issues such as color inconsistencies, misalignments, or print defects.

- Packaging and Delivery

- Once the printing and finishing processes are complete, package the products for delivery. Ensure they are protected during transit to maintain the quality until they reach your customers.

Conclusion

The printing process is a critical phase in creating effective cardboard packaging with your own print. By understanding the different printing methods, weighing their pros and cons, and incorporating advanced finishing techniques, you can ensure your packaging not only looks great but also aligns with your brand’s identity and meets your quality standards. With careful planning and attention to detail, your custom packaging can become a powerful tool for enhancing your brand’s presence in the market.

Common Mistakes to Avoid in Custom Cardboard Packaging Design

Designing cardboard packaging with your own print can significantly enhance your brand’s image and customer experience. However, there are common pitfalls that businesses often encounter during this process. By being aware of these mistakes, you can ensure your packaging stands out for all the right reasons.

Design Pitfalls That Can Undermine Your Packaging

- Overly Complex Designs

- While creativity is crucial, overly complex designs can clutter your packaging and make it difficult to read. Stick to a clean, simple design that clearly communicates your brand message. Effective packaging design often benefits from a less-is-more approach.

- Ignoring Brand Consistency

- Consistency is key in branding. Ensure that your packaging design aligns with your overall brand aesthetic, including colors, fonts, and imagery. Inconsistent design can confuse customers and weaken your brand identity.

- Poor Quality Images and Graphics

- Using low-resolution images or poor-quality graphics can detract from the professionalism of your packaging. Always use high-resolution files and ensure your design elements are crisp and clear to maintain a high-quality appearance.

- Inadequate Consideration of Printing Limitations

- Different printing methods have their own limitations and strengths. Ensure your design is feasible with your chosen printing method. For example, intricate details may not print well with flexographic printing, which is more suited to bold, simple designs.

Quality Issues to Watch Out For

- Color Inconsistencies

- Color consistency is crucial for maintaining a professional appearance. Make sure your printer uses the correct color profiles and conducts regular quality checks to avoid variations in color across different batches.

- Misalignment and Registration Issues

- Misaligned prints can make your packaging look unprofessional. Ensure your design elements are properly aligned and that your printer conducts thorough checks during the printing process to prevent registration issues.

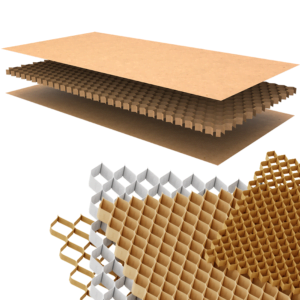

- Material Quality

- The quality of the cardboard used for your packaging is just as important as the design. Ensure you choose a durable, high-quality cardboard that can withstand handling and shipping while maintaining its appearance.

Ensuring Your Packaging Meets Industry Standards

- Compliance with Regulations

- Packaging must comply with industry standards and regulations, including labeling requirements and material specifications. Familiarize yourself with the relevant regulations in your industry and ensure your packaging meets all necessary criteria.

- Sustainability Standards

- Consumers are increasingly concerned about the environmental impact of packaging. Ensure your cardboard packaging with your own print is made from sustainable materials and consider using eco-friendly printing methods and inks.

- Functional Design

- Your packaging should not only look good but also be functional. Consider the practicality of your design, including how easy it is to assemble, fill, and transport. Test your packaging to ensure it protects your product effectively and provides a good customer experience.

Conclusion

Creating effective cardboard packaging with your own print requires careful attention to design, quality, and compliance. By avoiding common pitfalls such as overly complex designs, inconsistent branding, and poor-quality images, you can create packaging that enhances your brand’s image and meets your customers’ expectations. Additionally, ensuring your packaging complies with industry standards and is made from sustainable materials will help you build a positive brand reputation and appeal to environmentally conscious consumers. In the next section, we will explore expert tips and trends to make your cardboard packaging truly stand out in the market.